Always make sure the GrooveCenter is properly set up and zeroed. Look here for instructions

|

We need to make a groove exactly 5/8” wide on the edge of this board. There won’t be much left on either side so let’s not risk flipping the board end for end to make another pass. Unless it was right first time, this will eat away the thin walls (and make the groove wider than the intended 5/8″). |

|

Using the GrooveCenter there is no need to measure the board’s thickness, but just for fun: this is what it is.

We were not going to do any maths, but this is what the wall thickness should be: 0.726” – 0.625” = 0.101”. So that’s 0.050” on each side. Let’s see what the result will be! |

|

To set the fence, we drop the GrooveCenter’s Collet Pin into the router arbor and enclose the board between the Carriage and the End Plate. The fence just kisses the Fence Pin. |

|

This is what it looks like from above. A fence insert with just enough clearance for the Collet Pin Support is useful. |

|

Otherwise, with a split fence, just open it enough for the same clearance. |

|

With the fence secured and the bit at the correct height, the routing operation is a matter of seconds. |

|

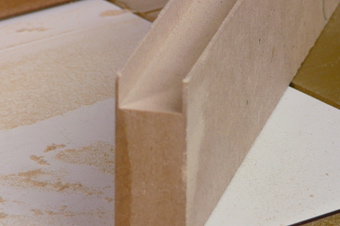

Here’s a perfect result, in less than a minute, without any measuring. |

|

The caliper shows 0.047”. That’s close enough! |

|

And most important: because of the single pass with the router bit, the groove is exactly the right width and perfectly centered. |

Related Articles